Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

1~2/unit

USD 23,000.00

≥3/unit

USD 18,000.00

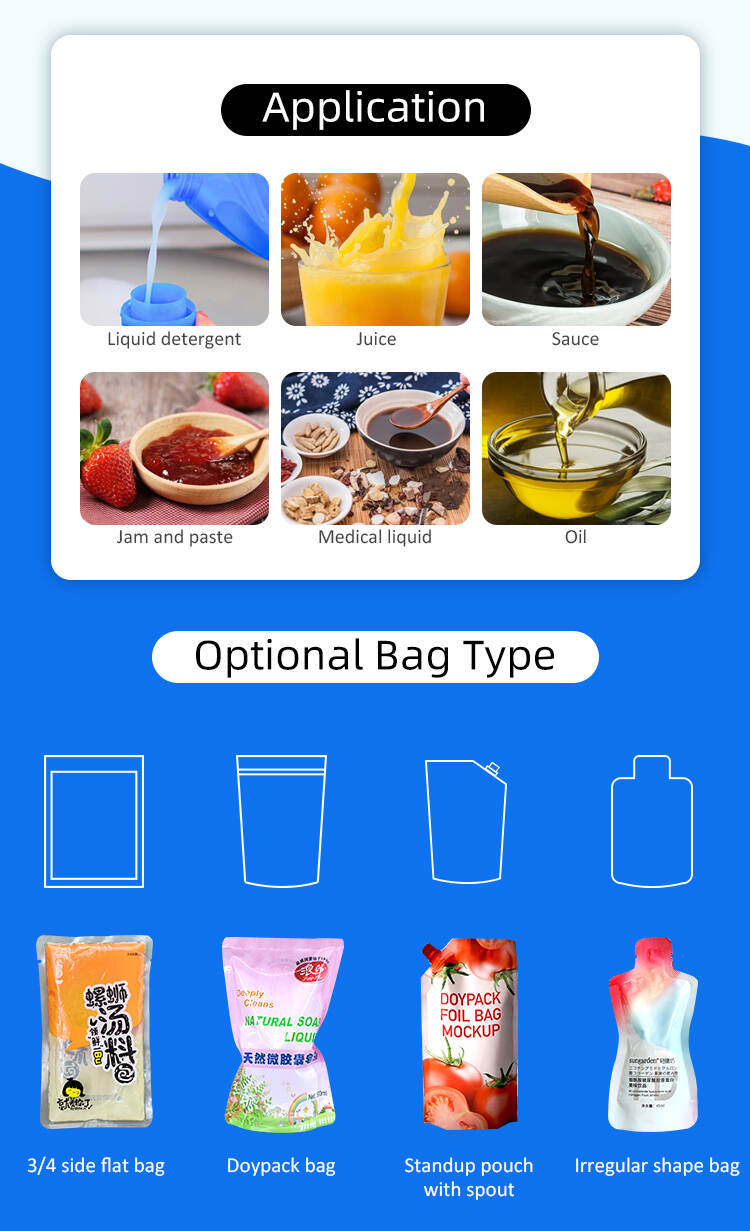

ZE-200RPL Rotary Doypack Packing Machine is a high-speed, precision solution for liquid products like shampoo, fabric softener, liquid detergent, and other viscous fluids in premade stand-up pouches. Designed for 200ml to 2L fills, this rotary-type machine achieves 50 bags/minute with ±1% accuracy via servo-driven pumps. Its stainless-steel construction ensures compliance with hygiene standards, while the PLC touchscreen allows quick adjustments for bag sizes, fill volumes, and sealing parameters. Features include automatic bag feeding, nozzle filling, gas flushing (optional for foam control), leak-proof sealing, and batch coding. Ideal for FMCG manufacturers in personal care, home cleaning, or cosmetics industries seeking contamination-free, high-volume packaging. Boost efficiency and reduce waste with the ZE-200RPL – engineered for reliability in demanding production environments.

| Parameter Sheet | |||

| Model | ZE-200RPL | ZE-250RPL | ZE-300RPL |

| Bag width | 80-200mm | 130-250mm | 160-300mm |

| Bag length | 100-350mm | 100-360mm | 180-450mm |

| Packing speed | 10-45 bag/min | 10-40 bag/min | 10-35 bag/min |

| Filling accuracy | +/-1%(per product) | +/-1%(per product) | +/-1%(per product) |

| Power supply | 380V 50/60Hz, 5KW | 380V 50/60Hz, 6KW | 380V 50/60Hz, 7KW |

| Air supply | 0.6MPA | 0.6MPA | 0.8MPA |

Machine Features

1.Different machine models are available to meet a wide range premade bag size.

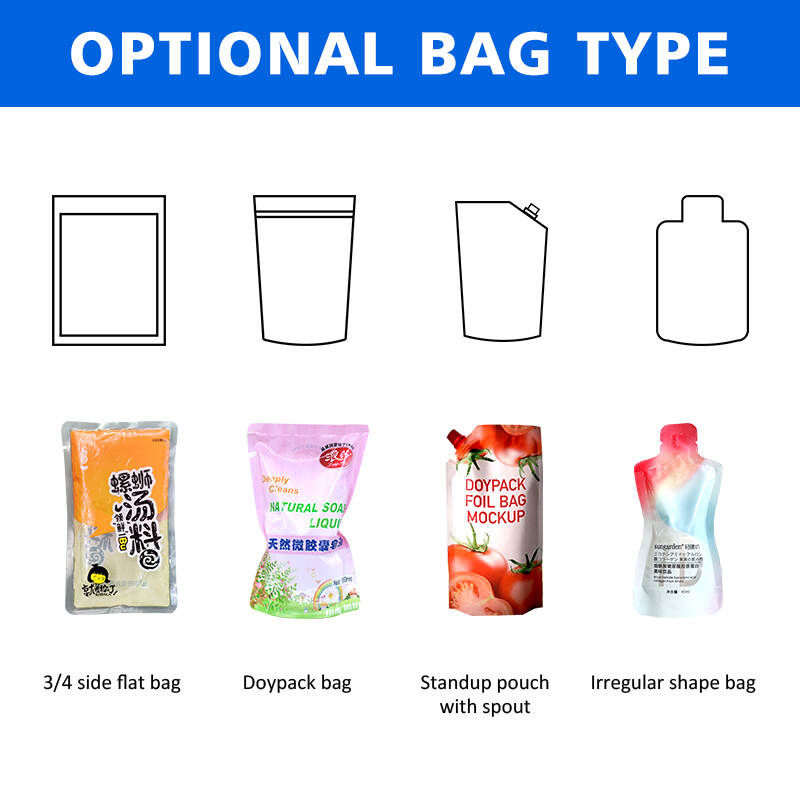

2.Customized rotary machine structure for various kinds of bag shapes. Like 4 side seal bag, doypack zipper bag, stand up bag, M shape gusset bag, corner spout bag, irregular bag,ect.

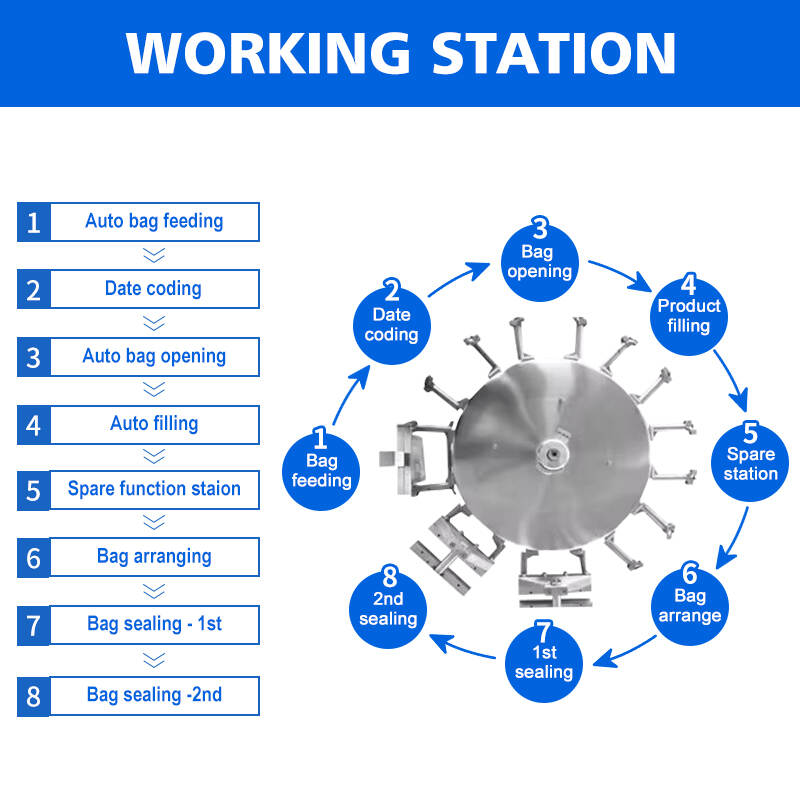

3.Machine with 8 working station to meet full automatic process of bag pickup,date coding,bag opening, product filling, spare station, bag arranging, bag sealing and output.

4.With upgrade PLC and HMI control system for easy operation and parameter adjustment.

5.Machine of multi-function that equips with different metering system like weighing scale, liquid pump, auger filler, bucket chain for different kinds of product auto filling and packing in premade pouches.